Objective

Ongoing requirement for piping and structural maintenance puts pressure on bedspace, with multiple site visits the norm. Emergency repairs are difficult to organise – requiring reorganisation of flight and personnel schedules at short notice.

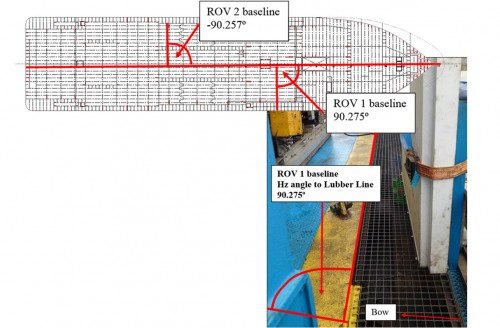

Requirement for Vessel Calibration to ensure that all Navigation equipment is reading true: position, heading, pitch & roll and confirm antenna, sensor offsets relative to vessel / position & heading.