Objective

Client purchased existing offshore oil platforms and onshore refineries in Turkmenistan. The facilities had minimal records and these were required for modification, maintenance and safety considerations.

Objective

Client purchased existing offshore oil platforms and onshore refineries in Turkmenistan. The facilities had minimal records and these were required for modification, maintenance and safety considerations.

NB Solution

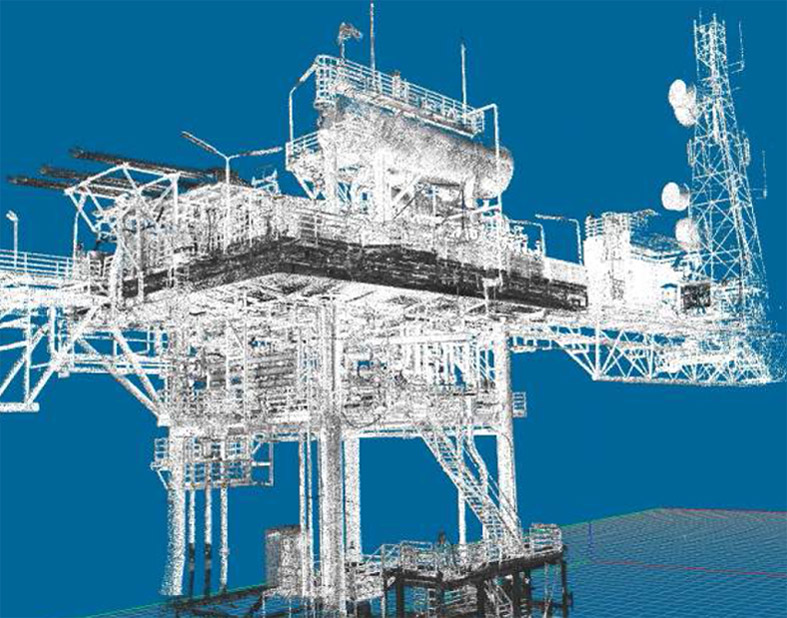

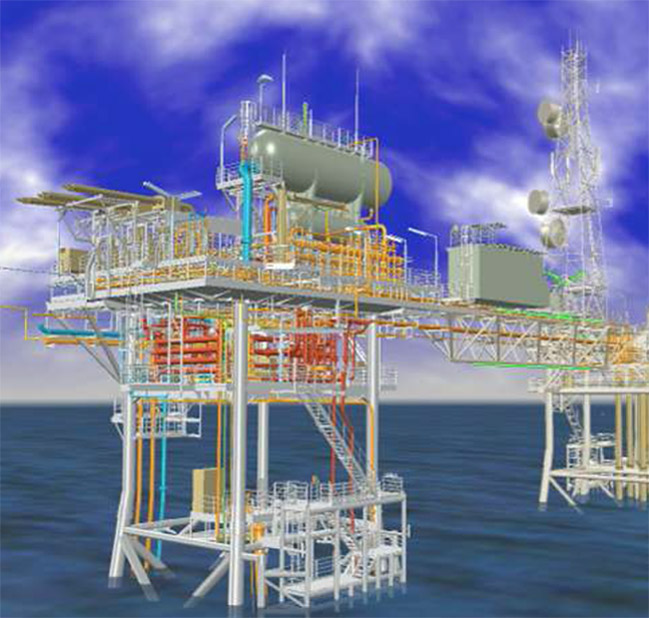

The four platforms were scanned in only 30 days. The scan data was processed and converted to accurate 3D models of the facilities, which were used to generate a fully functional PDMS Model.

The 3D Cad model was then used to reverse engineer the missing and incomplete drawings covering structural, piping, electrical, instrumentation, mechanical, safety, fire and gas and P&ID’s. Various additional deliverables were created to allow understanding and visualisation of the facilities. This was particularly important given the remote location of the platforms.

Benefits